Positioning

Custom-made products Positioning

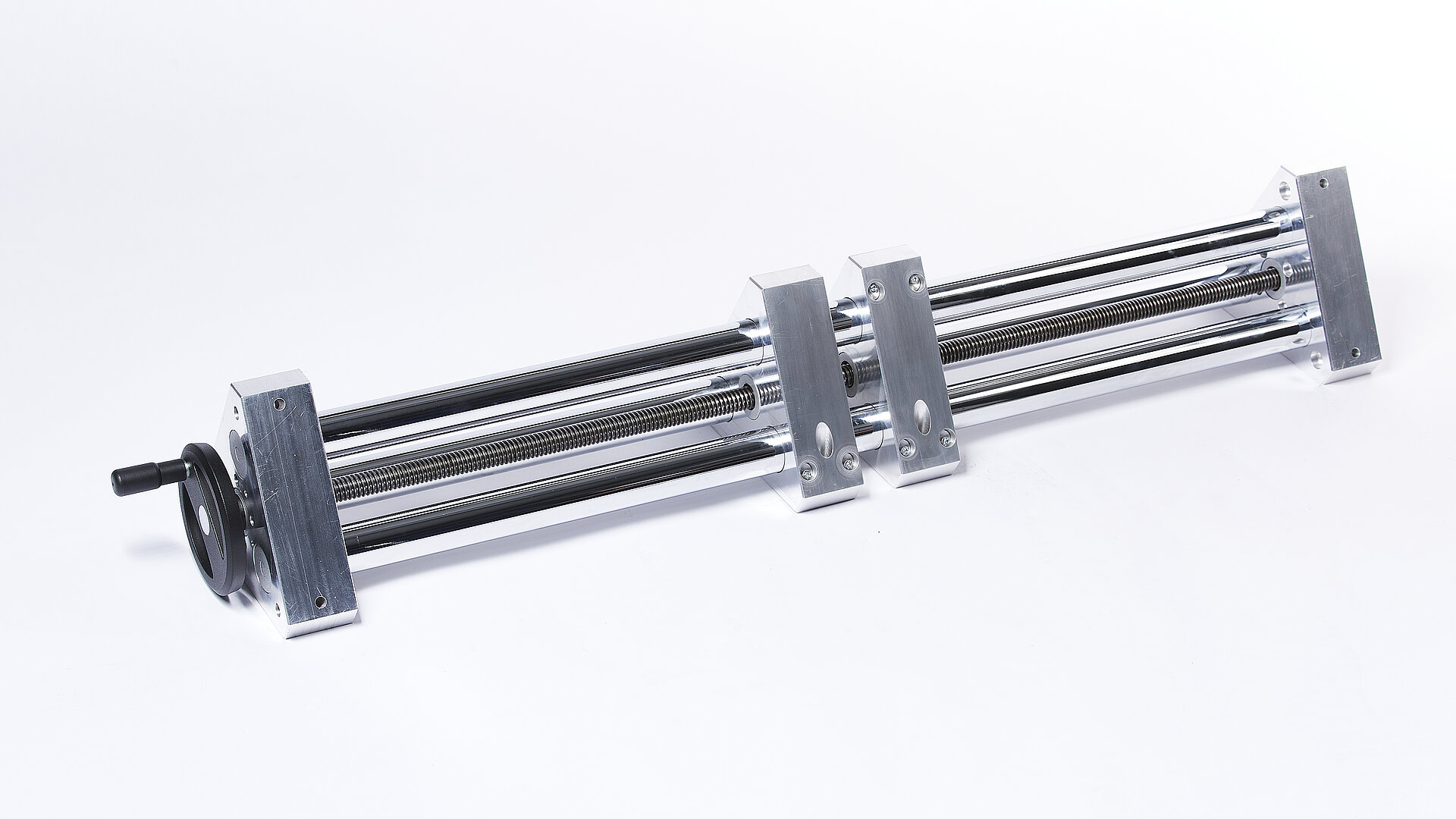

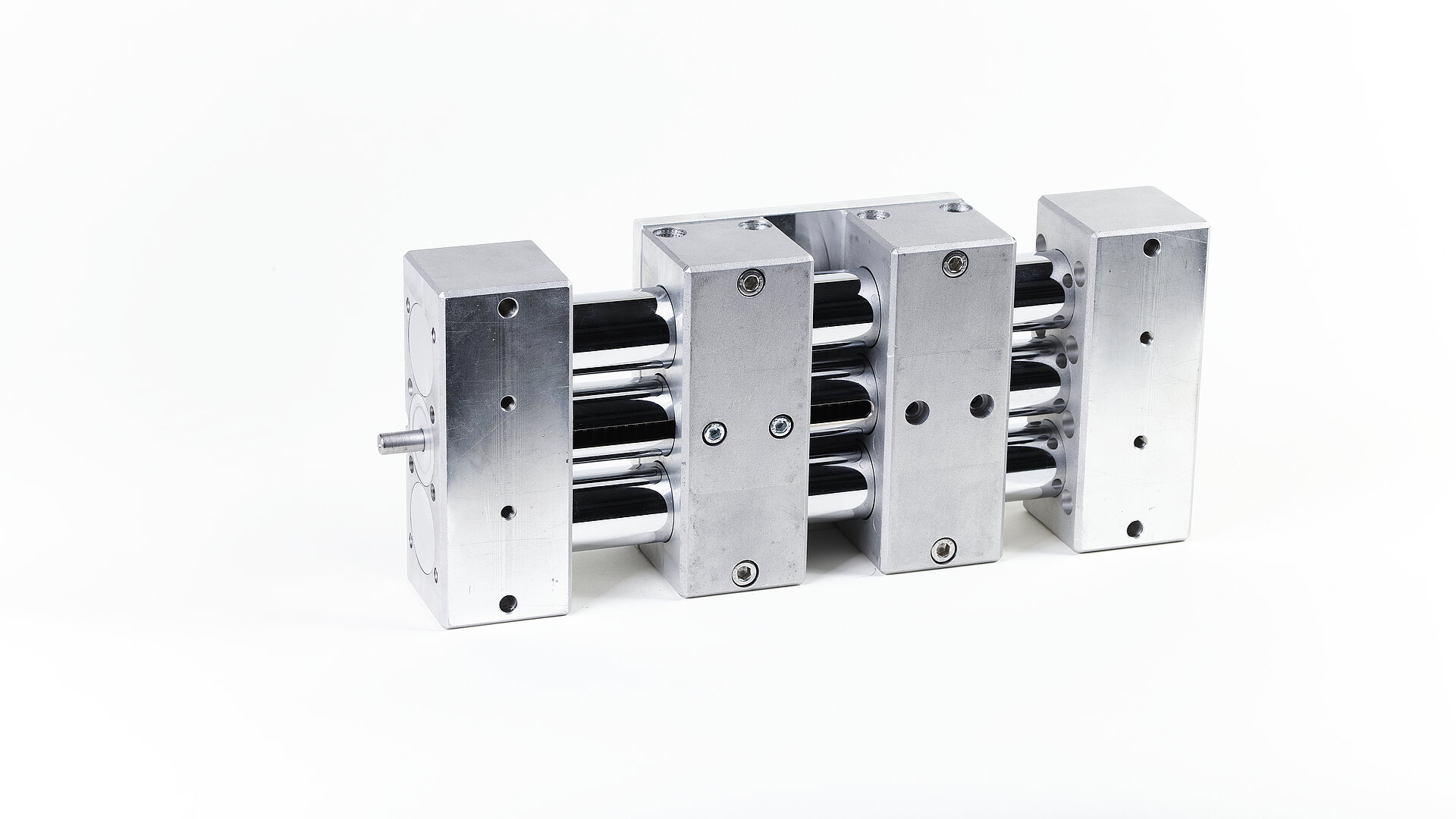

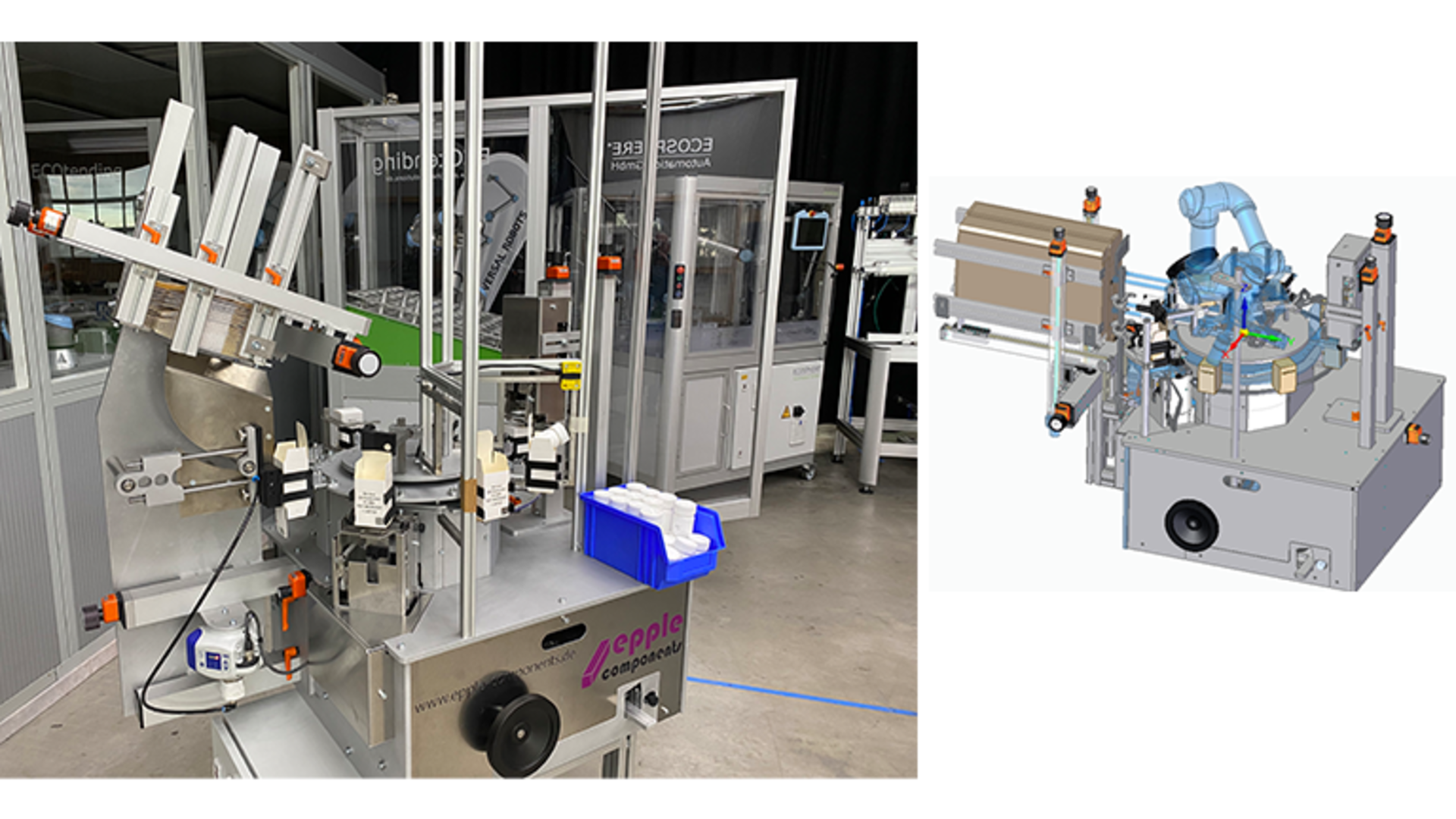

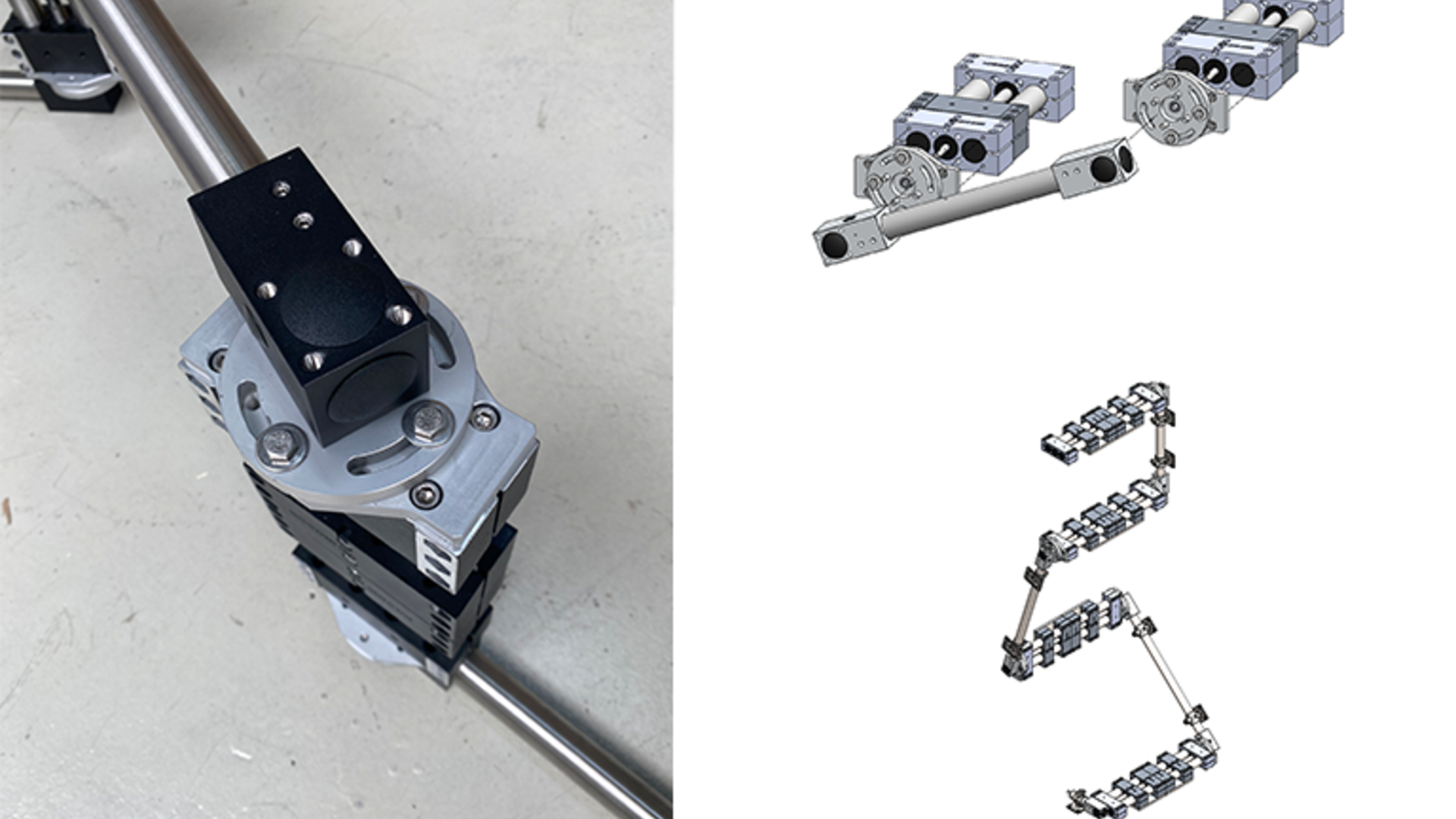

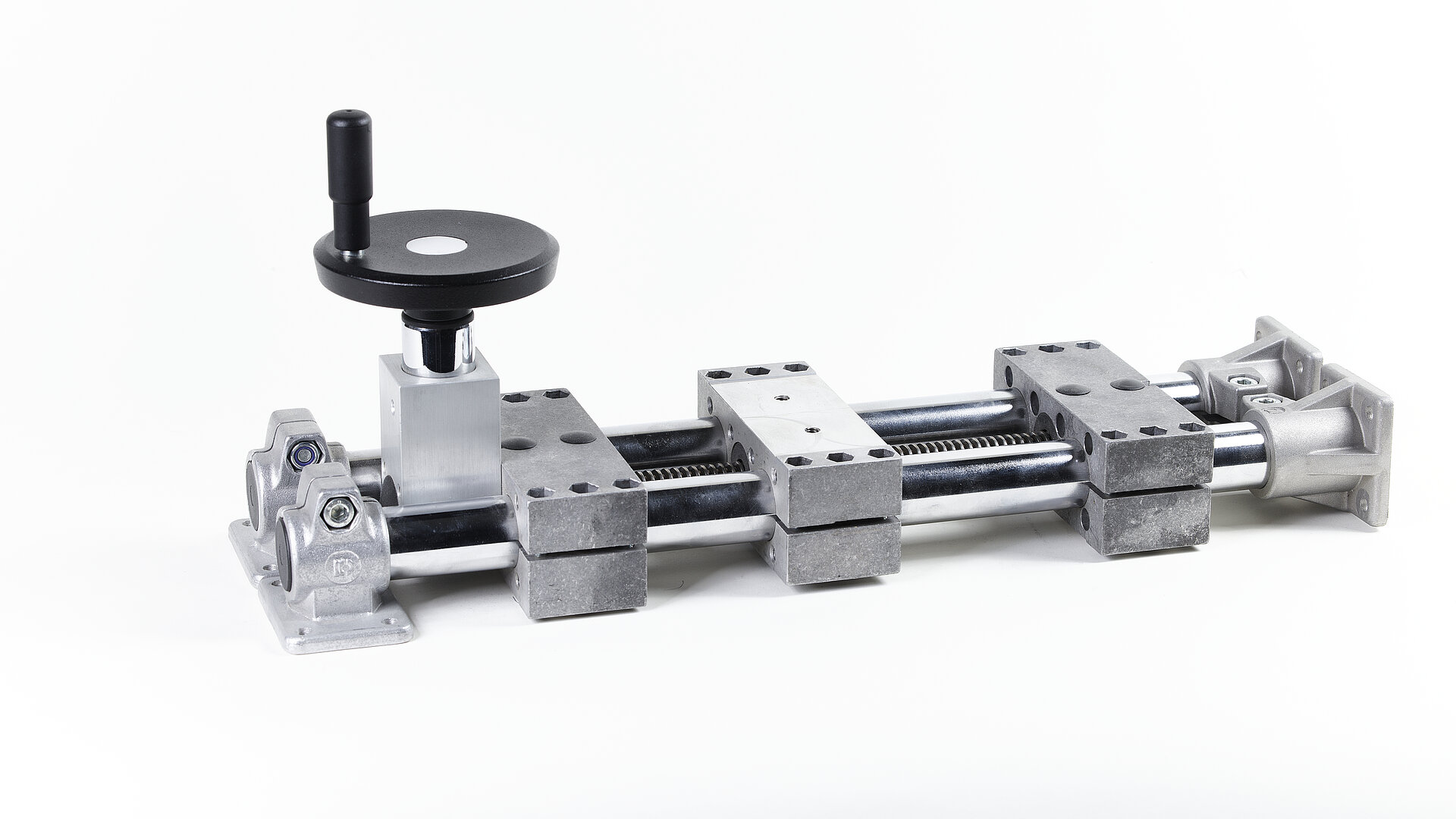

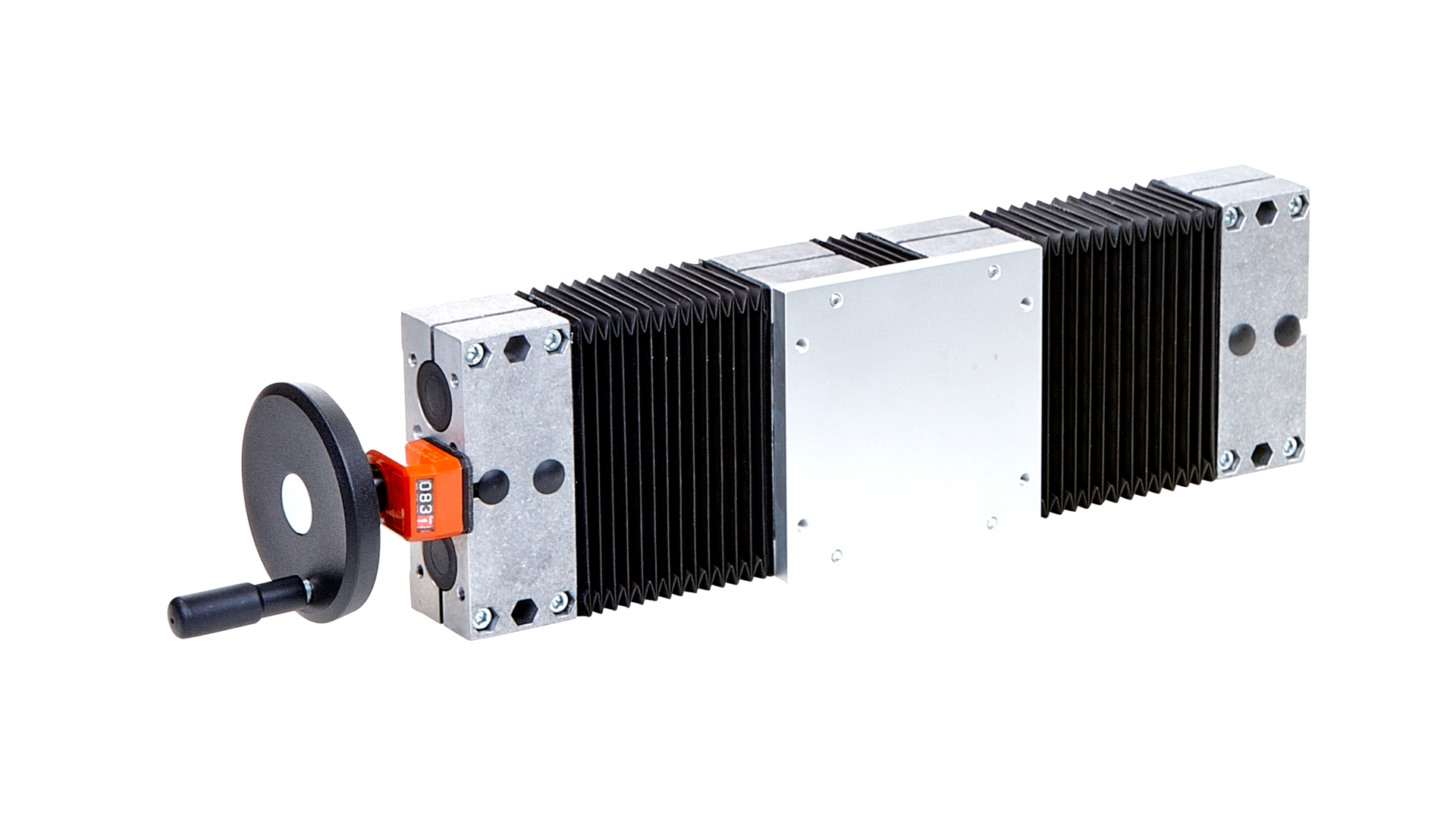

INOCON specializes in the manufacture of single and double tube adjustment units. These technically simple components offer high reliability and maximum flexibility. They can be moved either manually or by motor. The precision of INOCON linear units can be adapted to the user's requirements. The guides are suitable for both rough work and applications with tight tolerances.

Below, we present our custom-made products in this area.