What types of linear systems are there?

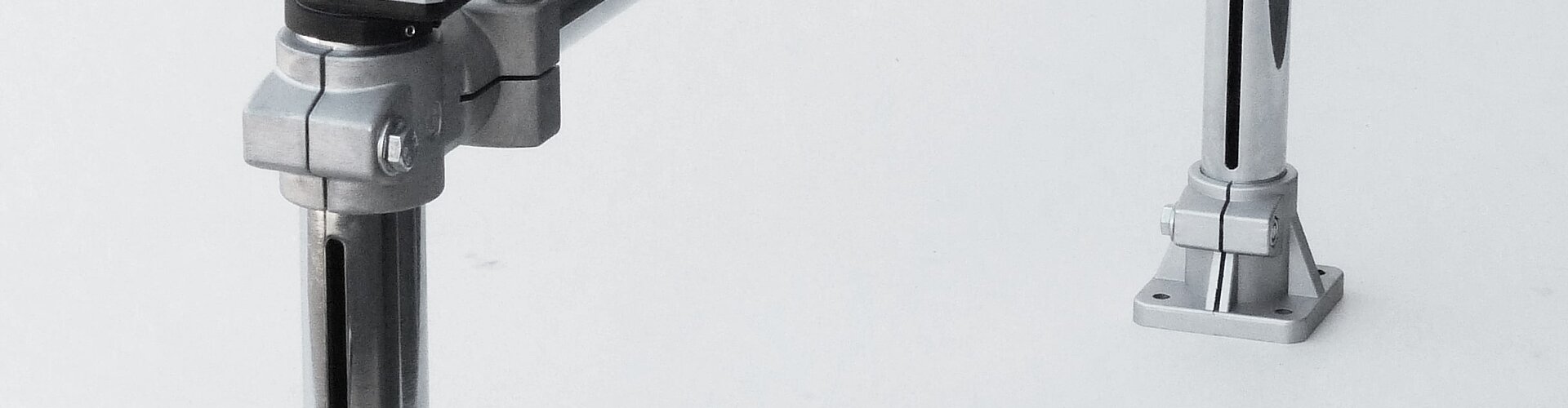

Linear guides are used to move a load along a specific straight path. They differ from radial guides, which move the load in a circular path.

Linear systems are designed to perform translational movements in either direction with consistent, repeatable precision. Due to the limited freedom of motion, linear systems are "uniformly accelerated."

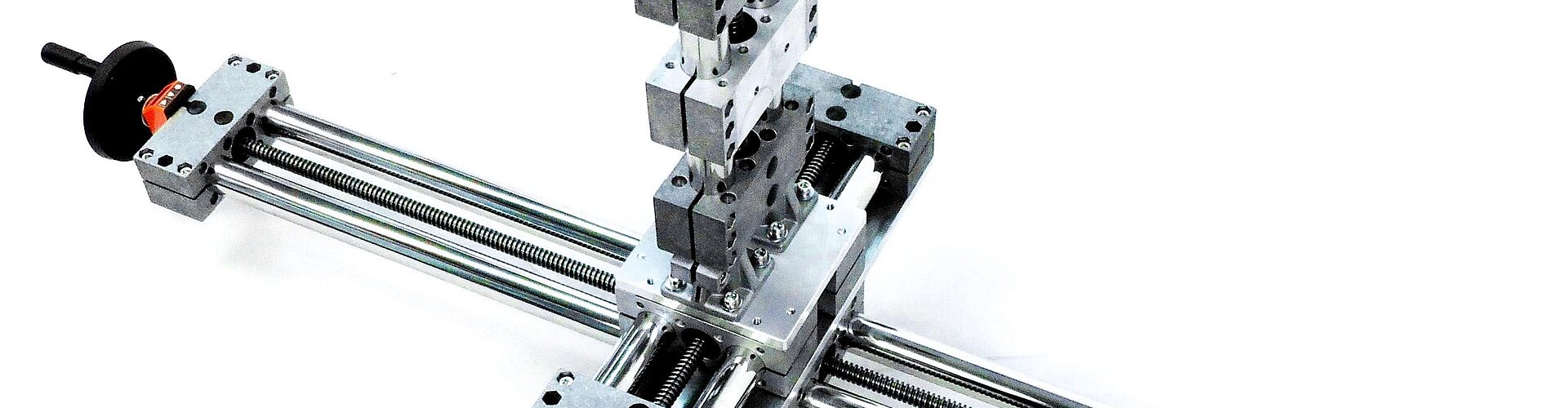

Linear guides make use of either slide rails or roller rails to control the movement. Slide rails consist of a small number of parts and operate very reliably after an initial run-in time, and they promise long services lives as a result. They have self-braking properties in the event of a power failure, which makes them very safe to operate.

Roller rail linear systems have lower friction and require correspondingly lower drive forces. In particular, the force required to overcome the resting inertia is negligibly low in industrial roller rail linear systems. In contrast to a slide rail guide, roller rail guides offer good emergency running properties. In the event of a power failure, the roller rail guide will continue its movement to the end before stopping. Depending on the application, this may be desired and advantageous.

Areas of application for linear systems

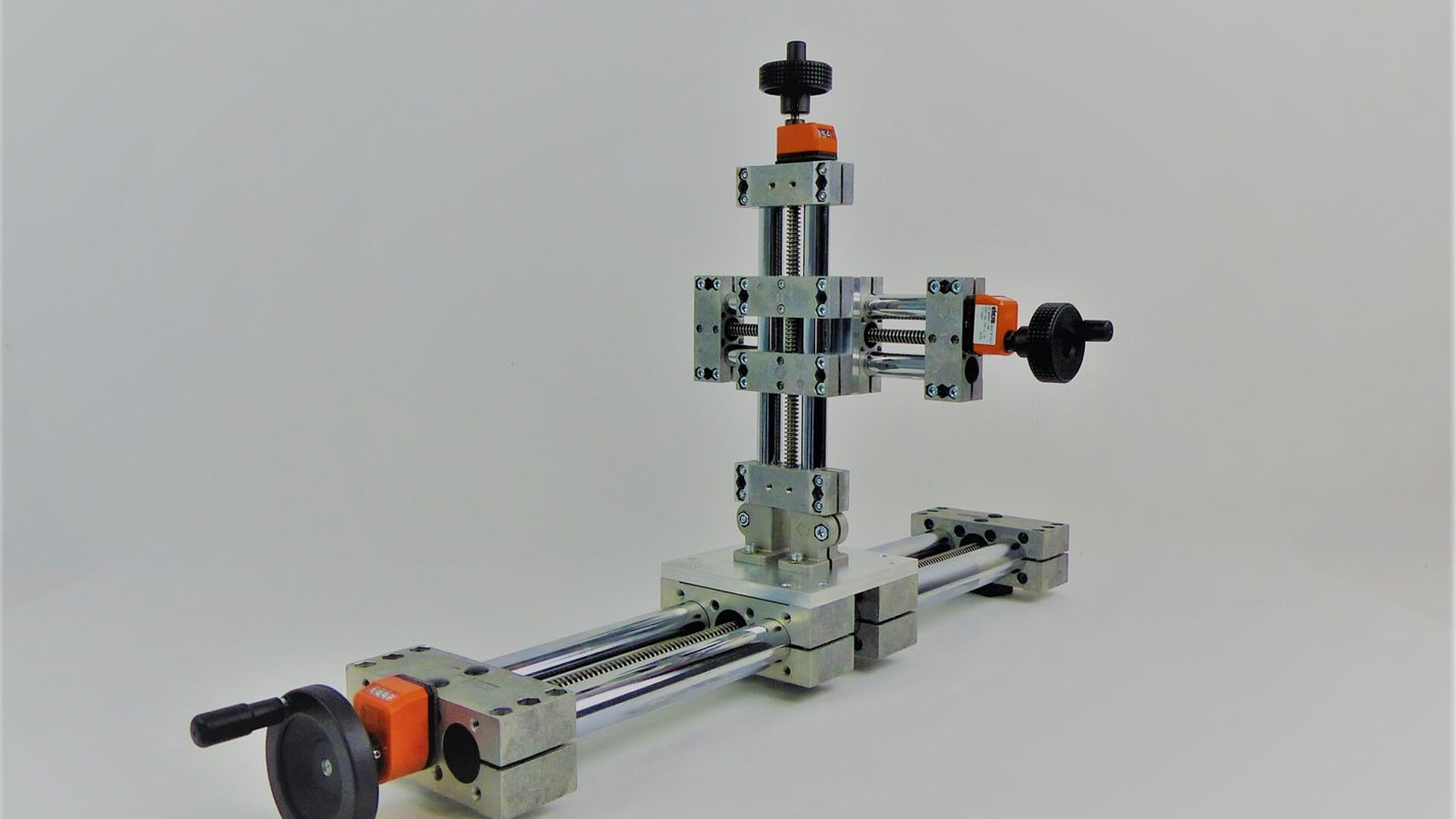

Linear systems are used in machines and for product transport within production plants. They can be combined into guide systems that enable movements within three-dimensional space. This makes them suited to the following areas of application:

- Pick-and-place systems for processing or packaging machines

- Tool guidance for product machining (e.g. CNC milling) - Sliding doors, flaps and hatches- Positioning systems for precise workpiece handling

In addition to three-dimensional applications, linear systems are used successfully for one- or two-dimensional tool or workpiece guidance. The range of applications is extensive. Precise movement along a defined path is the key feature of every linear system.

Why are linear systems important and useful?

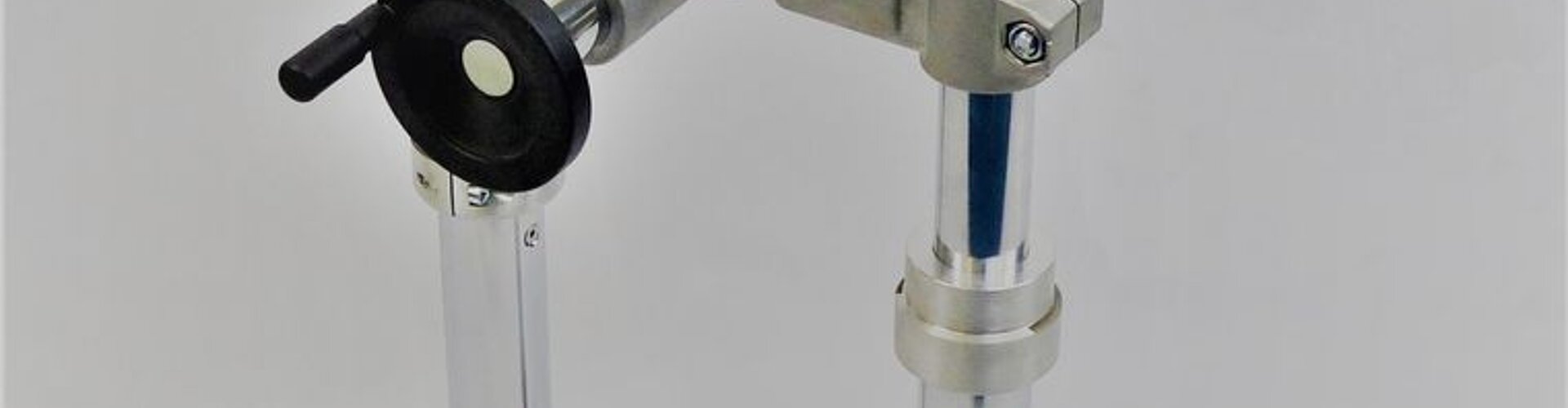

Linear systems ensure the movement of a tool or workpiece along a defined path up to a specified point. Regardless of whether it is a purely manual roller track with blocking function or a programmed gear rack drive with incremental encoder, the result is always the same: The movement is executed with consistent, repeatable precision. This is essential to make automated manufacturing and transport solutions possible at all.

Plain slideways and roller slideways

Plain slideways are inexpensive, simple linear systems that offer high reliability. They have self-cleaning and self-braking properties. Plain slideways require some time to run in so that the sliding block and the rail can wear each other in. After the run-in time, plain slideways maintain consistently reliably precision over long service lives.

Roller slideways

Roller slideways use recirculating ball systems or roller tracks to move the load along the desired path. They feature more small parts, are more expensive, and are more subject to wear than plain slideways. On the other hand, they offer lower friction and can ensure more uniform motion.

Roller slideways tend to be subject to soiling. Particles or fibers can jam the rollers and ball bearings. This causes the friction to increase significantly, making the motion less uniform. It is therefore recommended that they be cleaned and lubricated regularly.

Modern sliding blocks with micro recirculating ball steering combine the advantages of plain and roller slideways. They use form-fitting, wrap-around sliding elements. On the inside, they contain small recirculating balls in enclosed cages. These serve to reduce friction to an absolute minimum. Lubrication nipples situated on both sides allow lubrication and cleaning of the roller slideway. The act of injecting new lubricating grease forces out any dirt particles. This ensures reliable operation of the roller slideway and a long service life.

Contact

Do you have a special challenge in the field of research and development? Then contact us! We look forward to your inquiry and will help you find just the right solution for your application.